Шукаєте інструменти, які можуть виконувати ефективну обробку? Потім виберіть основи ZXGLW від штампу назад конусні фрезерні різаки! Ми з Китаю, професійного виробника, і маємо власний склад для підтримки постачання місця. Продукти включають різні типи металургійних різаків з вольфраму, крани, датчики нитки тощо. Якщо у вас є якісь потреби, ви можете зв’язатися з нами в будь -який час. Сильні індивідуальні виробничі можливості - це наша гарантія для вирішення вибору інструментів для вас.

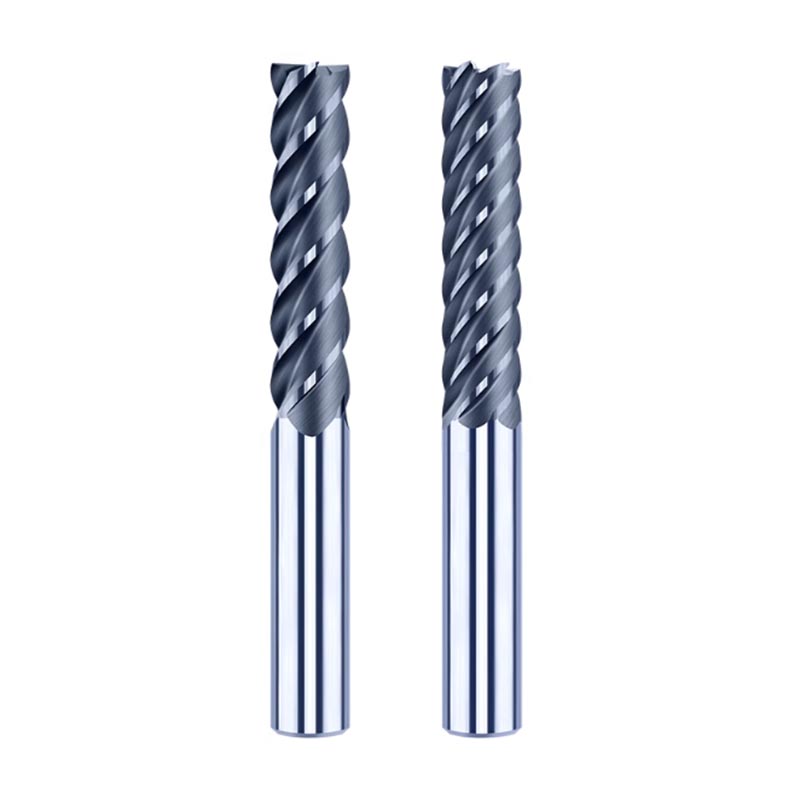

High-quality steel is the cornerstone of tool performance. The material of die base back taper milling cutters is top-notch high-quality steel, with a cutting hardness of HRC less than or equal to 55°-65°. It can be said that it has high hardness and toughness, which is the inherent guarantee of the durability of the milling cutter.

Compared with many peers who are still using ordinary steel, we spare no cost to exchange for higher wear resistance and life of the milling cutter, reduce the cost and time consumption of your tool replacement, and bring you convenience.

ZXGLW's die base back taper milling cutters adopt a full grinding process. This process has high requirements for technology and equipment. We have introduced advanced CNC grinding equipment, and with the cooperation of an experienced technical team, we carefully grind each cutting edge to achieve the desired sharpness and processing efficiency.

The four-edge design of die base back taper milling cutters combined with a unique angle of 65 degrees can cut into the workpiece more efficiently and conveniently, and the cutting force is evenly distributed. Compared with some milling cutters on the market with rough cutting edges and unstable cutting performance, our cutters are more stable in processing, show more ideal surface effects, and are not picky about materials, from ordinary metals to high-strength alloys.

1. Large core diameter design: The large core diameter design is an innovative design adopted by ZXGLW. It is a bold breakthrough in the original product. It can increase the rigidity and shock resistance of die base back taper milling cutters and avoid the phenomenon of broken cutters during processing as much as possible.

This is after our actual test. Compared with traditional milling cutters, especially when facing high-speed and large-feed processing conditions, milling cutters with large core diameter design can maintain stability and processing accuracy. Other traditional milling cutters are prone to tool vibration, reduced processing accuracy and even broken cutters.

2. Nano coating: The surface of die base back taper milling cutters is covered with nano coating, which provides low friction coefficient and thermal stability. It is mainly to reduce the friction between the tool and the workpiece, reduce heat generation, and work together to improve wear resistance. Die base back taper milling cutters can process a variety of materials such as die steel, cast iron, stainless steel, 45# steel, etc.

Customer needs guide our production. Whether it is die base back taper milling cutters or other cutting tools in our factory, they are all complete in specifications and can meet different industries and different processing needs. From machinery manufacturing, mold processing, to aerospace and automotive parts production, you can find suitable specifications in our product series.

If you have special needs, you can also contact us for customization. The geometric shape, dimensional accuracy and coating process of the tool can be personalized according to actual needs. We strive to be a good helper for your processing plan.

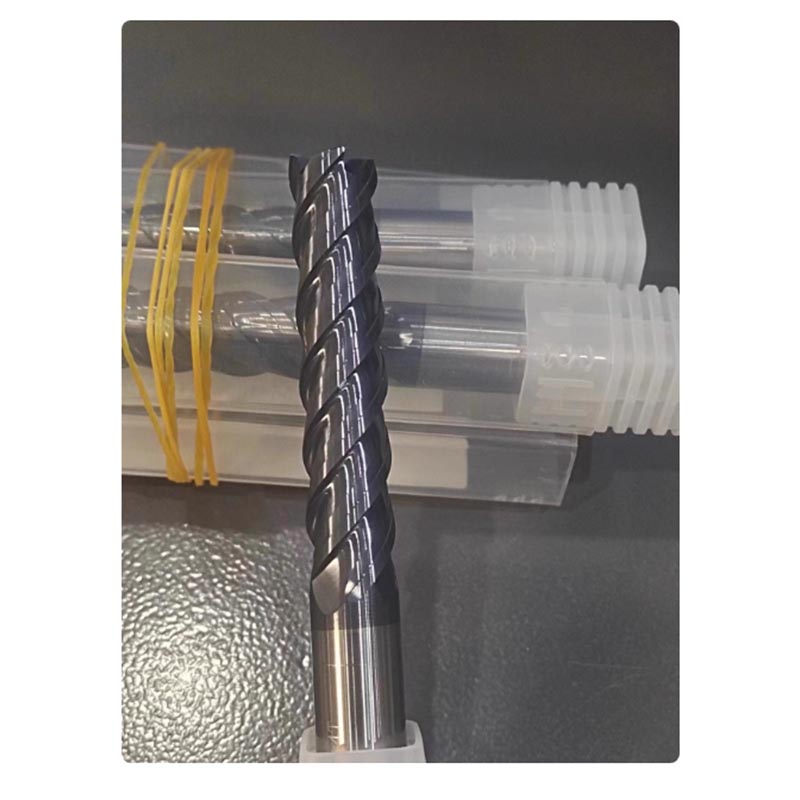

Die base back taper milling cutters are individually packaged and each box is equipped with special protective materials to avoid collision and scratches. This is our emphasis and pursuit of product quality, and it also provides convenience for your use and management.

Number of blades: 4

Cutting hardness: HRC≤55°-65°

Product material: imported tungsten steel

Processing materials: 45# steel, die steel, pre-hardened steel, stainless steel, cast iron, etc.

Applicable machines: CNC machining center, high-speed CNC milling machine, etc.

|

Blade diameter |

Shank diameter |

Total length |

Blade length |

Number of blades |

|

6 |

6 |

50 |

20 |

4 |

|

6 |

6 |

75 |

28 |

4 |

|

6 |

6 |

100 |

30 |

4 |

|

8 |

8 |

60 |

25 |

4 |

|

8 |

8 |

75 |

30 |

4 |

|

8 |

8 |

100 |

40 |

4 |

|

8 |

8 |

100 |

32 |

4 |

|

10 |

10 |

75 |

30 |

4 |

|

10 |

10 |

75 |

35 |

4 |

|

10 |

10 |

100 |

40 |

4 |

|

10 |

10 |

100 |

50 |

4 |

|

10 |

10 |

150 |

50 |

4 |

|

12 |

12 |

75 |

35 |

4 |

|

12 |

12 |

100 |

50 |

4 |

|

12 |

12 |

100 |

55 |

4 |

|

16 |

16 |

150 |

75 |

4 |

|

12 |

12 |

150 |

50 |

4 |

|

16 |

16 |

200 |

100 |

4 |

|

20 |

20 |

150 |

75 |

4 |